2) At least eight operating water mills in the one mile section down to the Tyne, in the eighteenth century.

3) Over thirty mine workings in the Winlaton locality, several of them in Blaydon Burn.

4) Winlaton/Blaydon Burn employers national leaders in workers rights and social care for all ages.

5) Crowley's Ironmongery Works (Winlaton, Winlaton Mill and Swalwell) Britain's, and possibly Europe's, biggest single integrated industrial production facility, in the early eighteenth century. It was a significant precursor to the industrial revolution. The coal came from nearby Blaydon Burn.

6) Winlaton iron and steel technical innovations lead indirectly to the foundation of the world famous Sheffield Steel.

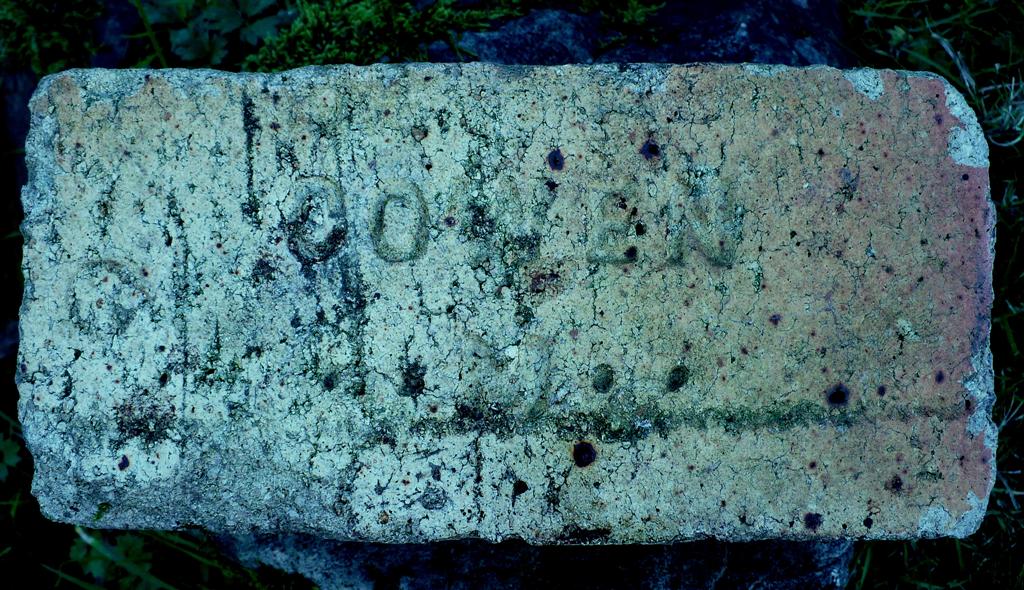

7) The best fire brick in the world? Well probably! At their peak, six million fire bricks a year from Cowen's two brickyards in Blaydon Burn.

8) State of the art, world leaders in power station turbine technology as installed by Parsons at Ottovale in Blaydon Burn.

9) Ottovale - the first place in the world to produce petrol from coal - Blaydon Benzol.

10) Giuseppe Garibaldi came to Blaydon/Stella - he was a close friend of radical MP Joseph Cowen. Did they wander up Blaydon Burn together, Cowen showing off his business interests and talking politics? More than likely!

Another major innovation, albeit at The Blackett-Beaumont Company (lead mining/refining) on land near where Blaydon Railway Station is now situated, and just along from the mouth of the burn. Here, in 1833, a brilliant chemical engineer, Hugh Lee Pattinson, developed a new crystallisation process which, by much increasing the silver concentration, much improved the cupellation method of extraction of silver from lead during the refining process. It was a discovery of international significance in the mining industry. Incidentally Pattinson invented other patents and went on to form his own company, The Washington Chemical Co. and to become an eminent member of The Royal Society.

Another employee, a Blaydon man, William Hall, had in 1816 developed a method of softening 'hard' lead enabling it to be efficiently smelted/refined with similar benefits. This was very significant to Tyneside in the later processing of Spanish lead which had very high silver content but was very hard and resistant to smelting etc.

How could one small patch of England be so significant? It's quite a story!

BLAYDON and WINLATON

Blaydon as a small town is not an ancient place. It grew from no more than a few farm hamlets and keelmen’s cottages with the arrival of the railway in the 1830s and due to the proximity to the River Tyne, both good for transport links. This stimulated a rapid growth of heavy industry during the industrial revolution. Conversely, the village of Winlaton just to the south (of which Blaydon Burn village is now a part) probably dates back to Anglo Saxon times or earlier, and is mentioned in the Bolden Buke, a twelfth century tax survey carried our by the Norman bishop Hugh Pudsey (Hugh de Puiset), Prince Bishop of Durham.

I was born in Blaydon in1946 and my teenage years were spent around old Blaydon and its surroundings. Boyhood adventures included escapades in the Blaydon Burn – clambering around the waterfall, playing on the old pathways and rail tracks, exploring up to the Benzol works and the ‘river of tar’, and so on – sometimes on foot, sometimes on my bike. The whole place was something of an adventure playground. At that age I was oblivious to the rather special history of this place. So here is some information about it, which I hope you find interesting.

Starting at the beginning - - -

BLAYDON BURN

Rising in the high ground near Coalburn Farm, south of the village of Greenside, a small stream winds its way north-east, descending between the villages of High Spen and Greenside. This is the Coal Burn and it is well named. The stream has existed since the end of the ice age and is a legacy of the retreating glaciers.

Now as the Barlow Burn, it flows on in an increasingly large valley as it progresses through delightful farmland passing the mysterious Reeley Mires, with its hill top silver birch wood, isolated farm and the distinctive undulating ‘inverted egg carton’ landscape here, which is a lovely example of glacial deposits. It passes north-west of the small village of Barlow, and then as Blaydon Burn, through Brockwell woods, then north-west of Winlaton and nearby Blaydon Burn village finally descending, in a substantial wooded dene, the final mile or so down to the Tyne at the western end of Blaydon, just west of the cottages at Horsecrofts and the nearby Black Bull pub. Nowadays it makes an ignominious entrance into the Tyne through a concrete conduit. It belies the little harbour that used to be there with space for mooring several keel boats.

Now, in this one mile lower section (as photographed above), the old Blaydon Burn waggonway is a designated walk and cycleway through the wooded valley where you can see a great variety of wild life and search out the industrial remnants still to be seen, some tucked away in hidden glades. When you look at the many stairways still there, which cascade from the steep valley sides, its very easy to imagine the workers in their work gear and carrying their bait boxes, trudging down from their terraced houses above, ready for a hard shift at the pit or works. These and the various remnants of bygone industries here creates a very striking atmosphere of a vibrant industrial past – it jumps out at you and its so easy to ponder the past here, and wonder what it might have been like.

Photos below - - -

Top left - Coalburns hamlet, south-west of Greenside. The burn rises near Coalburns farm.

Top right - The burn north of the High Spen/Greenside road.

Second left - Reeley Mires farm.

Second right - 'Who said you could wander round here? Leave me in peace'.

Third left - The burn valley, south of the Barlow/Greenside Lonnen.

Third right - The burn south-west of the Barlow/Greenside Lonnen.

Bottom left - Old steps giving workers access to burn from Winlaton to the east.

Bottom right - The ignominious entry to the Tyne via a concrete conduit. This used to be a small harbour for several keel boats before dredging in the 1870s made the river more like a canal here.

THE INDUSTRIES

There has been industry here since at least medieval times and probably much earlier. In the centuries following the middle ages and well before the industrial revolution gained momentum, it was probably one of the most industrialised pockets of land in the whole of England. In their heyday (seventeenth century) the mines round here were the biggest producers of coal in England, some of which was shipped to London for the making of lime mortar used for building construction.

During the industrial revolution and beyond (late eighteenth to mid twentieth centuries) there was an astonishing amount of industry here embracing mines, waggonways, forges, mills, brickworks, gas retort works, coal by-products and other related industries. All these built up from two vital resources – water power and coal.

COAL

The first recorded industrial activities in Blaydon Burn were coal mining and milling. The valley sides were ideal for drift mines giving access to the rich seam. The drift geology is alluvium (mostly glacial sand and gravel) overlying middle and lower coal measures. The seam here was known as the Brockwell seam. Further west at Stella and at Blaydon, was the Tulley or Stone seam. The Brockwell seam was considered the most valuable.

Central to this continued success was the Blaydon Burn waggonway, built by Joseph Cowen Snr. in 1840.

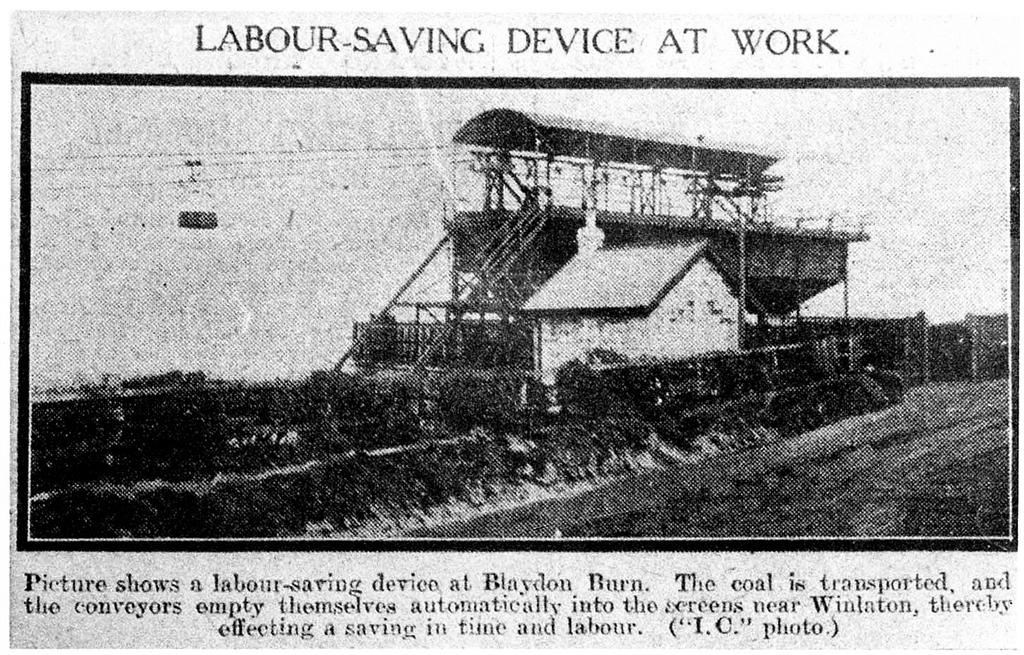

At its time of peak production there was even an ariel flight ropeway transporting coal in cable car chauldrons, from the Bessie Pit to the coal screening depot. (see picture right). To this day an area of Winlaton, near where the depot was situated, is known locally as 'The Flight'.

As the industrial revolution gained momentum and as engineering innovation (including steam engines for pumping away water) enabled the development of deep mining around Tyneside and beyond, the local coal output was gradually overtaken by higher output from the new deep mines to the east so that gradually its importance as a key producer dwindled.

The Blaydon Burn Waggonway was built following an agreement in 1840 between land owner Peregrine Edward Towneley and Joseph Cowen, giving Cowen much better access to his Tyne river quay, also the newly constructed (ie. 1830s) railway between Hexham and Blaydon (later Carlise to Newcastle).

Pictured below right are remnants of the Blaydon Burn waggonway retaining wall and structures, south of the lower railhead. Near the southern end the waggonway divides into two levels, upper and lower, leading to Cowen's High Yard.

Mine Ownership - -

After the Norman invasion much land passed into the control of Norman barons under their feudal system. Some also passed to the to the church. The king retained 25%.

Then, in the nineteenth century, the Cowens became major figures in the mine owning and political life of the locality. Gradually into the late nineteenth and early twentieth centuries mine ownership consolidated. In the great war all fell under government control. In the slump of the 1930s demand fell away leading to more consolidation.

Finally after WW2 came nationalisation, the NCB.

With acute competition from abroad (due often to much higher governmental subsidies) came the pit closures of the 60s onwards, such that after a wave of closures in the 1980s very few UK mines remained, leading to re-privatisation of the remaining few.

But at its peak there was a phenomenal amount of mining activity in the Winlaton/Blaydon locality (some drift, some shaft sunk) – below is an NCB list showing the scale of it – all within just a two or three mile distance from Winlaton village.

Alice Drift 1 - Winlaton

Alice Drift 2 - Winlaton

Ashtree Coal Drift - Winlaton

Barlowfield Drift 2 - Winlaton

Bessie Pit 1 - Winlaton

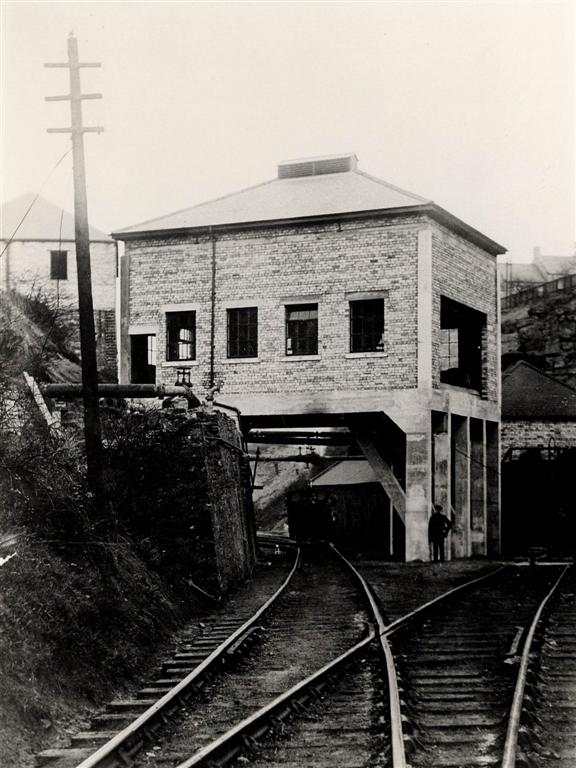

(pictured right as it was, then in the picture below,

the coal drops, as it is now)

Bessie Pit 2 - Winlaton

Betsey Pit - Winlaton

Blaydon Burn Colliery - Winlaton

Blaydon Cowens Colliery - Winlaton

Blaydon Main Colliery 1 - Winlaton

Blaydon Main Colliery 2 - Winlaton

Blaydon Main Hazard Pit - Winlaton

Blaydon Main Milner Pit - Winlaton

Blaydon Colliery - Winlaton

Cowens Blaydon Colliery - Winlaton

Derwenthaugh Colliery - Winlaton

Edward Pit - Winlaton

Garesfield Ashtree Colliery - Winlaton

Garesfield Colliery No. 3 Pit - Winlaton

Garesfield Lilley Colliery - Winlaton

Garesfield No. 2 Pit - Winlaton

Garesfield Ruler Pit - Winlaton

Garesfield Tilley Drift - Winlaton

Garesfield Towneley Pit - Winlaton

Gordon Pit - Winlaton

Gordon West Old Pit - Winlaton

Hazard Pit - Winlaton

Hookergate Drift - Winlaton

Landsate Pit - Winlaton

Lilley Drift - Winlaton

Lily Drift - Winlaton

Little Pit - Winlaton

Mary Drift - Winlaton

Mary Pit 1 - Winlaton

Mary Pit 2 - Winlaton

Milner Pit - Winlaton

Speculation Pit - Winlaton

Winlaton Colliery - Winlaton

Watermills were in use in Britain in Roman times and by the time of the Domesday Book, a Norman survey of 1086, there were more than 6,000 watermills in England. By the sixteenth century, waterpower was the most important source of machine power in Britain and Europe. The number of British watermills probably reached 20,000 by the mid nineteenth century.

The picture right is the 'other' Blaydon Path(Peth) Head Mill. There were two - one in the burn (now a ruin) and another just a few hundred yards away feeding from Stella Burn. This old corn mill has been beautifully restored and a visit is recommended. It is clearly signposted on the western side of Blaydon on the old Ryton road heading to Stella (B6317).

There is record of a mill in Blaydon Burn in 1183. Due to the eminently suitable geography there has, in the past, been a very significant amount of mill activity. Indeed the burn must have been the best place by far in the locality for milling as by the eighteenth century, in the northern one mile section of the burn leading to the Tyne, there were at least eight mills operational.

Most of these mills were originally corn mills although I’ve read there may also have been a fulling mill in bygone times. Also there were a smaller number of flint mills.

Pictured right is Wintrip's flint mill in Blaydon Burn.

Flint had various uses – in fire clay used for fire bricks, ceramics, in tools, etc.

Some mills were later used to power water pumps to help drain the mine workings and for iron working.

With the advent of steam power most of the mills fell into disuse so that by the beginning of the twentieth century they were virtually all closed down. Early map records are imprecise and also mills tended to take the name of the resident millwright and therefore changed as they moved on. Here is a list of the Blaydon Burn mills taken from various publications and maps - - -

High Mill/Dunn's Mill/Wintrip’s Mill (flint)

Forster’s Mill (corn)

Path Head Mill/Burn’s Mill/ Gibson’s Mill, Hobby’s (Hoplyh’s) Mill (corn)

Robinson’s Mill/Shipping’s Mill (corn)

Low Mill (flint, then corn, then clay)

Pickering’s Mill/Rennisons Mill/Haggerstone Mill/Fenwick’s Mill (corn)

Brockwell Mill/Belt’s Mill/Belt & Whitfield (corn)

Dockendale Mill/Massey’s Forge (a corn mill converted to a forge)

Of all of these three sites still have visible remnants in the burn, these are - - -

Low Mill

Path Head Mill (pictured right is the mill race as it is now)

Massey’s Forge - which has a particularly interesting history.

MASSEY’S FORGE

This corn watermill probably built in the 1700s became a forge in the early 1808. The two wheel pits suggest modification of the power source or operation as a double mill. That year the Silvertop’s Dockendale Estate rental included payment by Emerson & Co who were a family firm of ironmongers based in The Side, Newcastle who had extended into the iron foundry industry. By 1821 this included fire brick manufacture then steel, and a Thomas Milner was a partner in what was now Emerson & Milner. In 1837 the Dockendale Estate was dispersed but in the changes of lease Emerson & Milner managed to retain their site on a 31 year lease. This relative security of tenure may have encouraged the investment in a mine, the Milner Pit, which located several coal seams, this in the same year 1837.

Strange then that within one year there was fundamental change.

It would be then that Smith Patterson & Co’s ‘Pioneer Foundry and Engineering Works’ began as a foundry here. Brick ovens were built at the base of the dam. The firm made chairs for railway track, cast iron tunnel segments, etc. Smith Patterson eventually relocated to larger premises in Blaydon Haughs (The Spike) presumably for the good transport links (mainly the railway). It was to become a major employer on The Spike.

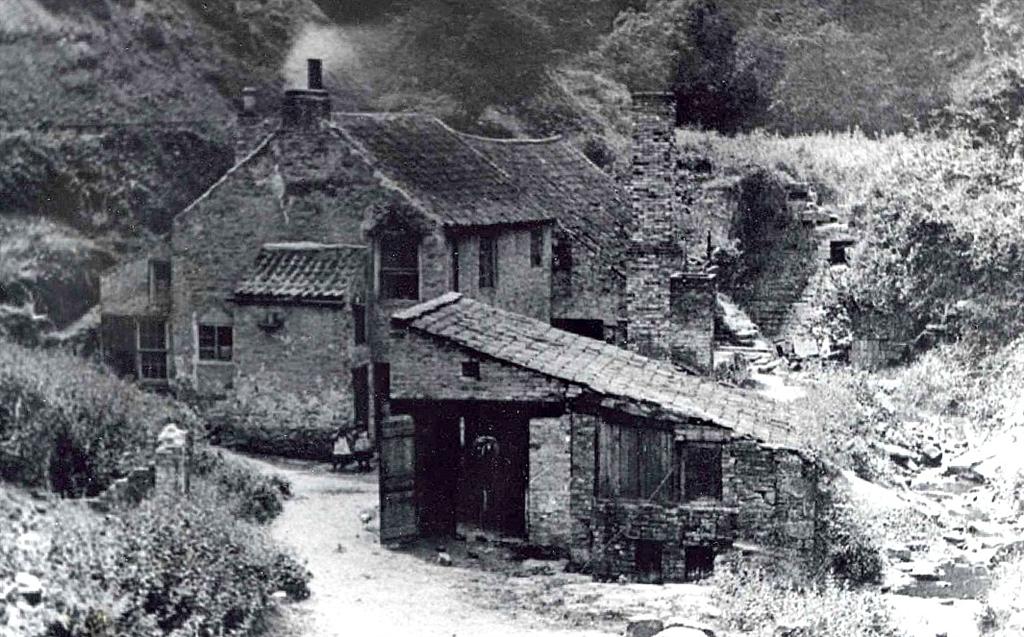

So sadly by 1896 this significant mill/forge was abandoned and already in ruins having in its final stages suffered the ignominy of being used as animal shelters. Ironically no one of the name Massey has ever been traced in connection with the site.

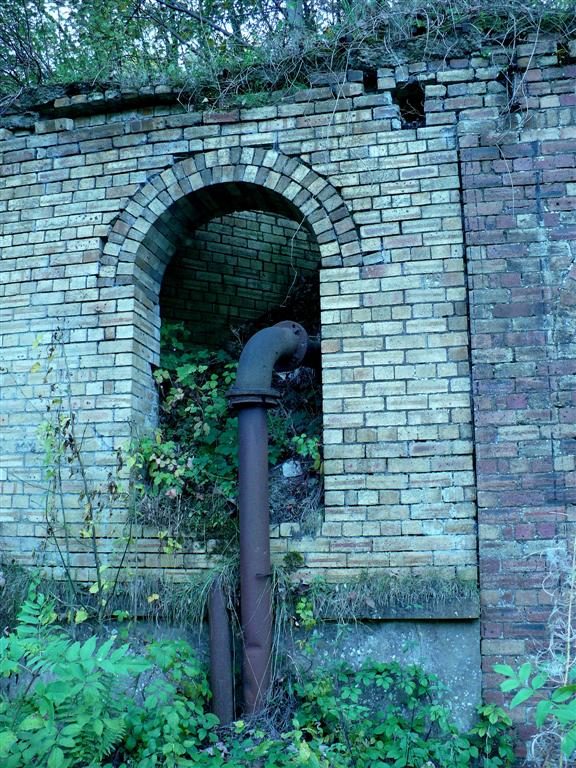

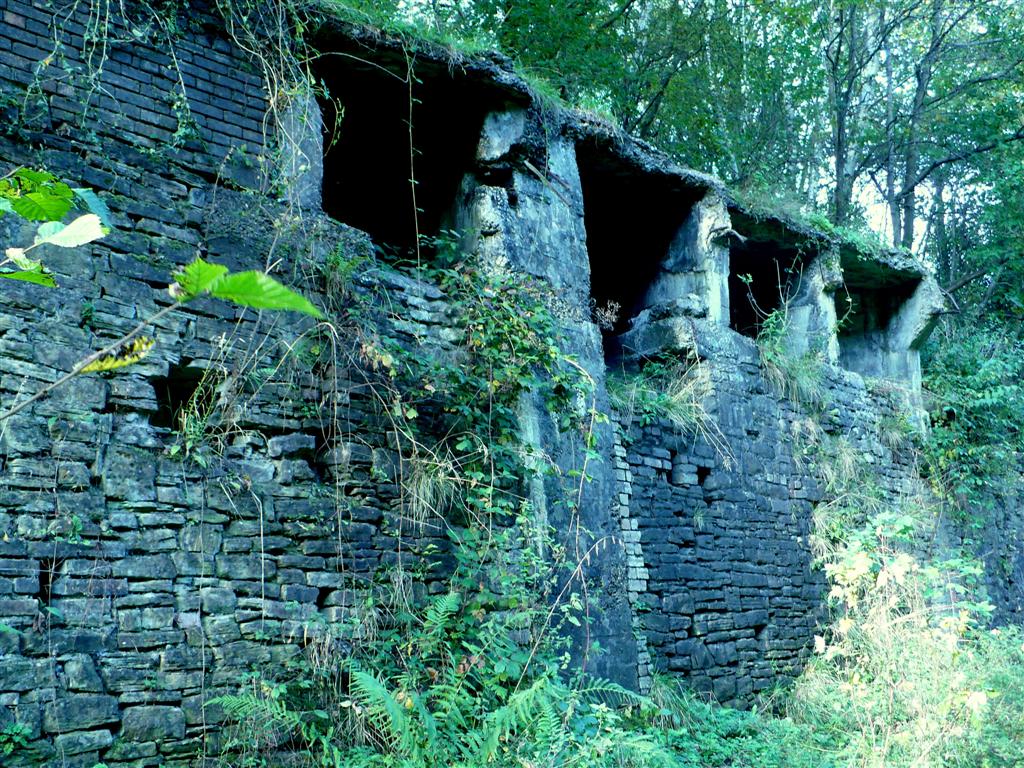

Pictured above is the retaining wall and buttress of the forge sluice/weir as it is now.

CROWLEY’S CREW and THE COWEN CONNECTION (Sir Ambrose Crowley 1658 – 1713)

As a child in Winlaton in the early 50s, I can remember two blacksmiths still working. One at the top of Parkgate Lane, the other in Hood Square.

Little did I realise these were the last of an amazing episode in Winlaton's long history.

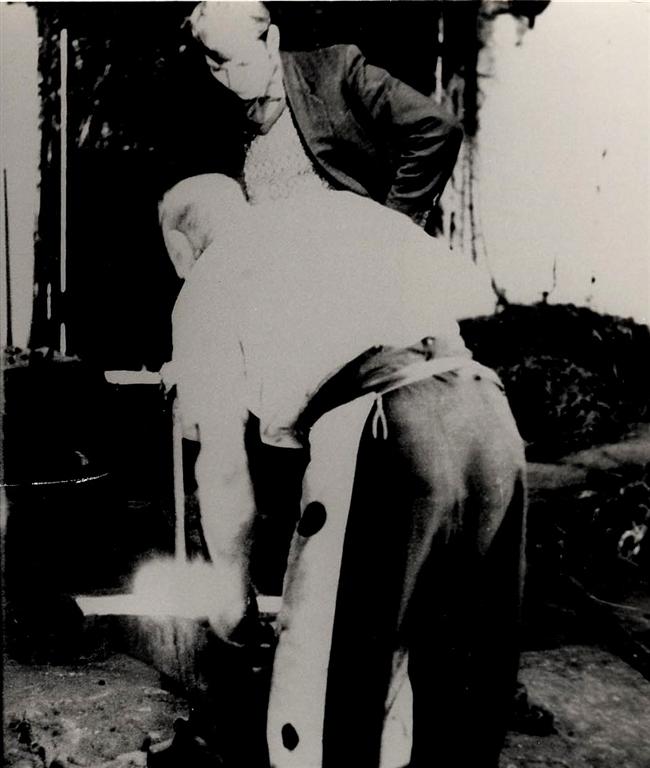

Pictured right is the blacksmith forging the very last chain, Winlaton Forge 1966.

Whilst only connected to the Blaydon Burn by virtue of the ready supply of fuel the great historical importance of Ambrose Crowley’s Winlaton ironmongery activities is undeniable.

The Crowley Ironmongery Works at Winlaton, then extended to Winlaton Mill and Swalwell, was probably, at the time, Europe's biggest industrial location. Today, Crowley is still known for his enlightened management methods. His workers had an elected works committee, sickness payments, company medical team and were treated with respect. These rules are set out in the 'Rules of the Crowley Iron'.

The blacksmiths mainly used imported iron, and both iron and steel were worked by the Heyford process. Technologies and skills developed at the works were to lead to the foundation of the Sheffield steel industry and to the ability to machine steel. The 'Crowley Crew' were renowned not only for their skills with metal but also their steadfast and resolute defence of their rights and freedoms in the face of government intimidation. In this respect the Crowley's Crew and the Keelmen were two formidable communities. Sometimes they fought good causes together, sometimes there were disagreements and rivalries.

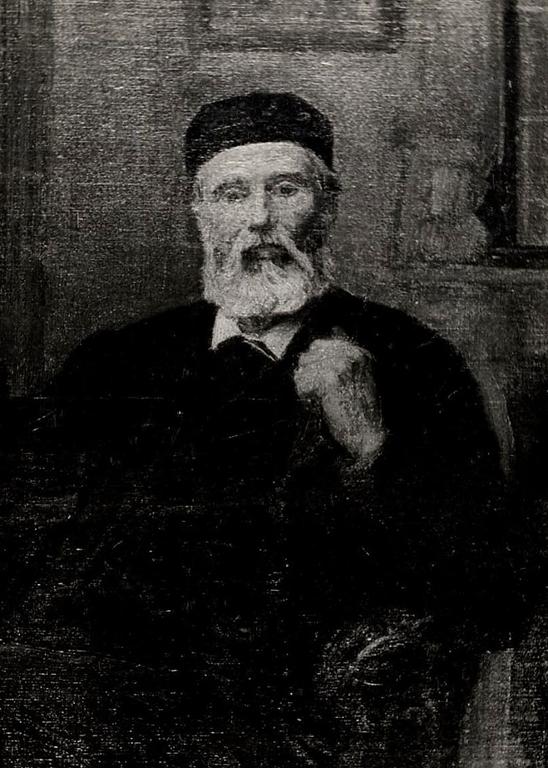

Joseph Cowen Snr began as a Crowley’s apprentice (as a chain maker) and eventually emerged as an extremely successful businessman in his own right. At the end of the Napoleonic Wars the business diminished and fragmented. It had been managed by Crowleys descendants. The blacksmiths of Winlaton formed a Friendly Society and Joseph emerged as secretary and was a driving force, before developing his business interests in Blaydon Burn. Crowleys ‘Quaker’ principles probably influenced his political thinking and man management ethic.

Joseph Cowen Jnr made a speech to Blaydon Burn Lodge of the Durham Miner's Union in Oct 1883, including this paragraph -

"When many busy centres of industry were moorland and forest, Winlaton was a seat of vigorous industry. The semi-socialistic experiment of Crowley was interesting both politically and industrially. It got together a body of workmen who gave distinctive character to the village, who afterwards acted as pioneers in the special trades in other districts. They lived largely in community; they began their work with a prayer; they ate together; they adjusted their differences with voluntary courts; they had a church and a school, a cock-pit and a bull-ring. They were stout church and king men, rough, but loyal." (Bourn)

Most coal seams have an underlying layer of fireclay. This was the case with the Blaydon Burn’s Brockwell seam and the pits in the burn mined the clay (and flint) as well as the coal. This enabled the growth of fire brick production, also other heat resistant products such as gas retorts, sanitary fittings.

One family, the Cowens, became synonymous with this local brick production such that the plain speaking Joseph Cowen Jnr. was given the nickname ‘The Cowen Brick’.

started working life as one of Crowley’s Crew in Winlaton. When Crowley vacated Winlaton, Cowen became something of a leader of the blacksmiths who remained. He then developed his own business and his entrepreneurial gifts enabled him to become a wealthy businessman from mining and the making of firebricks and other clay products, initially in Blaydon Burn then beyond. But just as Crowley had been a good employer with a social conscience, likewise Cowen was a good employer, liked by his workers. He became a radical politician who campaigned for democratic reforms (eg. voting by secret ballot). He became a Liberal MP for Newcastle 1865 – 1873. He was knighted in 1871 for his work as chairman of the Tyne Improvement Commission.

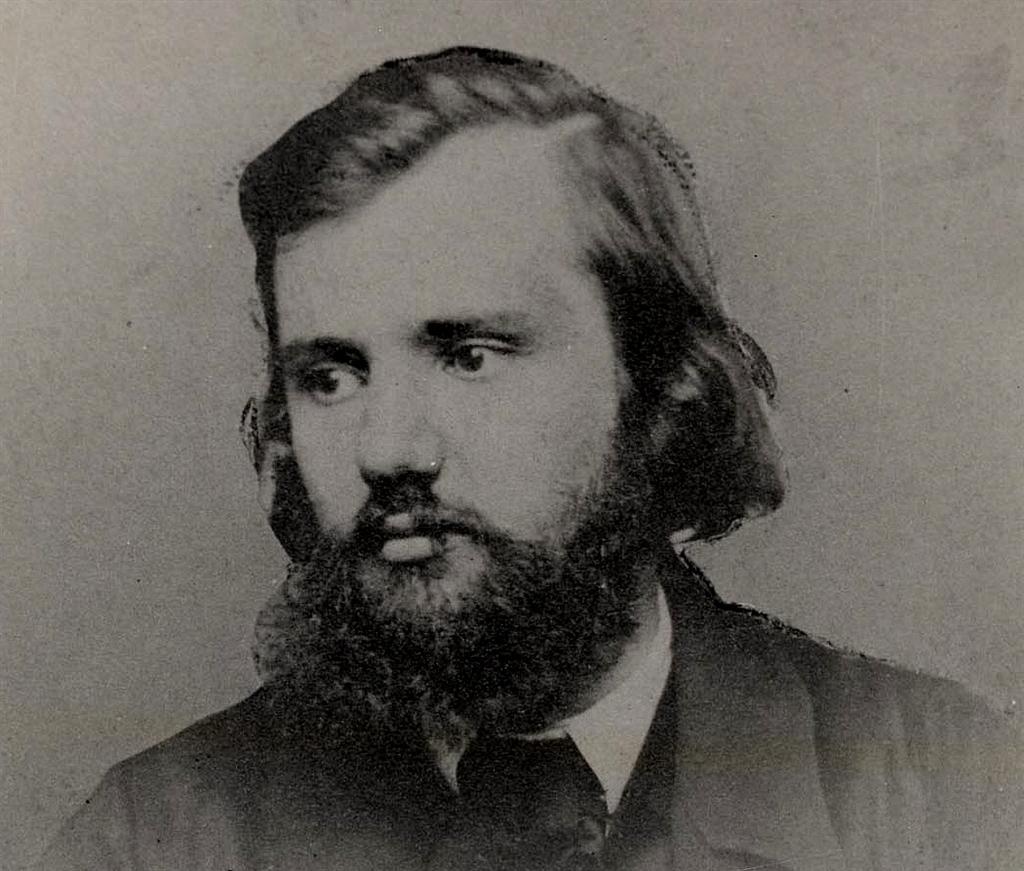

took over the business but was also a free thinking radical politician who fought for free education, the rights of the working classes and who was regarded as a very fair employer. He knew many European radicals including Garibaldi and Marx. Garibaldi visited Cowen at Stella on two occasions. Cowen’s statue of Garibaldi situated on Blaydon’s Summerhill sounds like the stuff of myth but happens to be fact. The statue head is now in Blaydon Library. Cowen was allegedly under surveillance from foreign intelligence officers for smuggling revolutionary texts in consignments of bricks! He followed his father as MP for Newcastle but retired from parliament in 1886, disillusioned with its methods. He had a reputation in parliament as blunt, unsophisticated and plain speaking but was admired for his honesty, integrity and caring social principles.

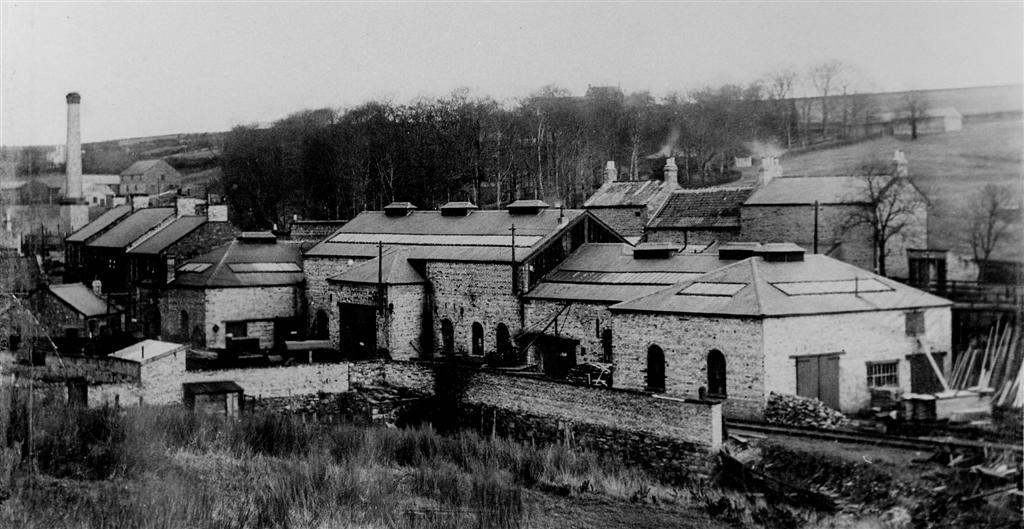

The Cowens developed two significant brickworks in the burn.

'Cowens Low Yard' – opened in 1838. It closed in 1975. The site, pictured right, was at the northern end of the burn, adjacent to the old Blaydon to Ryton Road and just west of Horsecrofts. It has now been cleared and is a wild flower meadow. Some of the old kiln and coal-drop walling remains.

‘Cowens High Yard’, pictured below right, was at the southern end, west of but near Winlaton. Situated alongside his Mary and Bessie Pits for a ready supply of coal and clay it was also a major producer of firebricks, coke, gas retorts and other clay products. It had originally been tenanted by John Forster and operated as a ‘firebrick manufactory’, this being in the late 1700s.

The Bessie Pit also had coke ovens and a coke grading platform which ran along by the burn wagon way.

At their peak the two Yards made six million firebricks a year.

Cowen also eventually developed mining and related industry operations around the locality and beyond Blaydon Burn.

One in particular, the Lilley Drift Mine at Rowlands Gill, gave rise to an adjacent brickworks using the coal and clay.

PRIESTMAN COLLIERIES LTD

Following the Cowen era the next significant organisation in the Blaydon Burn's history was the Priestman group of companies. Joseph Cowen Jnr. passed away in 1900 and Priestman Collieries took over the Cowen holdings. They registered as a Limited Company in 1903. The directors were from Shotley Bridge. In 1909 they owned the mines listed below, plus the remarkable 'Ottovale' Coke & Tar Works and Power Station, also situated in Blaydon Burn, this under a separate company.

Axwell Park

Blaydon Burn Bessie

Blaydon Burn Mary

Chester South Moor

Lilley

Victoria Garesfield

Waldridge A

Waldridge D

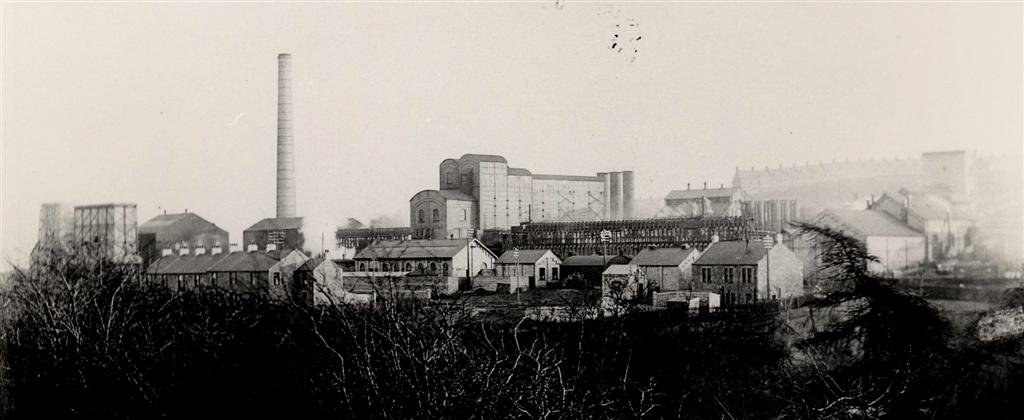

I remember this huge industrial complex well. It was situated at the eastern flank of Blaydon Burn on the site of the old Dockendale Hall (home of the land and mine owning Silvertops). All the locals referred to it as 'The German Ovens'.

So much for loyalty - the Luftwaffe tried hard to bomb it in WW2!

It had three industrial components - a coke works, a tar works and a power station.

It was built in 1904 by the Priestman Group. The eighty coke ovens were made by the Otto Hilgenstock company of Germany.

'Priestman Power Station' (aka Blaydon Burn Power Station) - this was owned by 'Priestman Power Company' until 1914 then 'Newcastle upon Tyne Electricity Supply Co.' up to 1948. Nationalisation then brought the British Electricity Authority (1948/55) and Central Electricity Authority/Generating Board (1955/59). It was decommissioned in 1959.

It used the waste heat generated by the coke ovens. The Parsons equipment used was of the latest and best design in existence. Initially used to supply power to the mine, on takeover in 1914 it also supplied power to the rest of County Durham.

Feed water for the boilers was taken from the Blaydon Burn however, there wasn't a sufficient amount of water available for condensing purposes as well, and so the condensing water needed to be used over and over again. This necessitated the construction of a cooling tower and reservoir.

In 1916, the station's generating equipment was replaced by a 3,000 kW Parsons generating set. This was the first generating set in the world to use reheated steam between stages in its turbines, and to progressively heat feed-water using partially expanded steam.

In 1919 the station was further modified, becoming the first station in the world to use an enclosed ventilating circuit for the alternator with a gilled-tube cooler for extracting the heat from the ventilating air, which overcame problems caused by dust and moisture getting into the windings.

When the UK's national grid distribution system was brought into use in 1932, the station was one of a small number of stations in the region to be converted from the 40 hertz(Hz) frequency used by the North Eastern grid system to the 50 Hz frequency used by the national system.

The station ceased operating in 1959. Reclaimation of the coke works began in the 1970s and the area has now been returned to grassland. An electrical substation still stands at the northern end of the site, accessed from the burn or a lane running down from Twizell Avenue, Winlaton.

'Ottovale Coke Works/Tar Works' - continued to be operated by Priestman Collieries Ltd until closure in the 1970s - this despite Priestmans mines having passed into national ownership by The NCB in 1947. It would seem there was still a close and beneficial working relationship between Priestmans and The NCB following nationalisation. The tar all went to Thomas Ness Ltd, a National Coal Board owned subsidiary dealing with coal based chemical by-products.

Priestman’s Ottovale Coke and Tar Works was the first in the world to produce petrol from coal. It became known worldwide as Blaydon Benzol.

BLAYDON BURN NOW

Some of Cowens old buildings still stand at the southern end – the high yard near Winlaton. They are today used by haulage and HGV maintenance companies.

All other industry had ceased by the 1970s and in the years that followed, various reclamation schemes treated and made safe most derelict sites. The burn was allowed to return to nature, the waggonway taken up and reverted to footpath.

Now a council designated nature reserve, the Blaydon Burn contains a wide range of habitats and wildlife.

Gateshead MBC deserves a lot of credit for developing this site as a fascinating local amenity. It is a unique place for walking and cycling and for appreciation of the industrial archaeology still to be seen (whether from the footpath or tucked away in leafy glades) as well as all nature has to offer here.

Pictures below - Four images of Cowen's High Yard as it is now.

Pictures below - taken in Blaydon Burn.

Top left - Comma butterfly.

Top right - Cornflower.

Bottom left - Peacock butterfly.

Bottom right - Broad leaved helleborine.

Blaydon old/new bridge over the burn, carrying the B6317 - just north of the reclaimed Cowen's Low Yard and nearby, Horsecrofts cottages.

Below are some winter photos, taken Dec 2010 by my son Stephen.

Resting Style - a correspondent, reseaching family tree, has traced an ancestor to this address. The house or cottage, with the lovely name 'Resting Style' was probably situated between Blaydon and Winlaton, possibly near March Terrace or in the vicinity of High Shibdon or Haggerston Mill. Does anyone have any information? If so please E Mail me via the home page.

Thanks Roly

Acknowledgement - sincere thanks to ISeeGateshead on line archive for the old b/w photos shown here. The recent colour photos are mine and the four b/w snow scene photos just above were taken by my son Stephen.

Roly Veitch

Updated 20th October 2014

For more information on our local area history, our unique dialect, our wealth of dialect songs and other topics please visit the home page menu - link below.

Back to Home Page