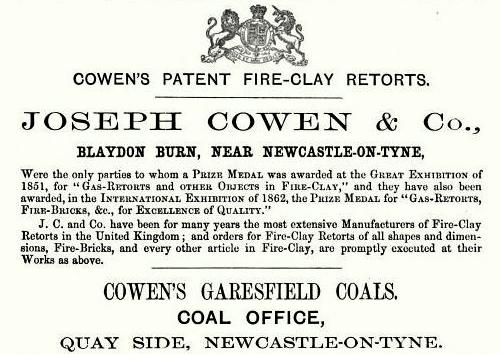

As with the well known lager advert the title caption may be tongue in cheek but in the case of Joseph Cowen's fire bricks (and industrial gas retorts) it might just be true for they were certainly among the very best. From his brick-yards in Blaydon Burn premier quality fire bricks and award winning retorts were made and exported all over the world.

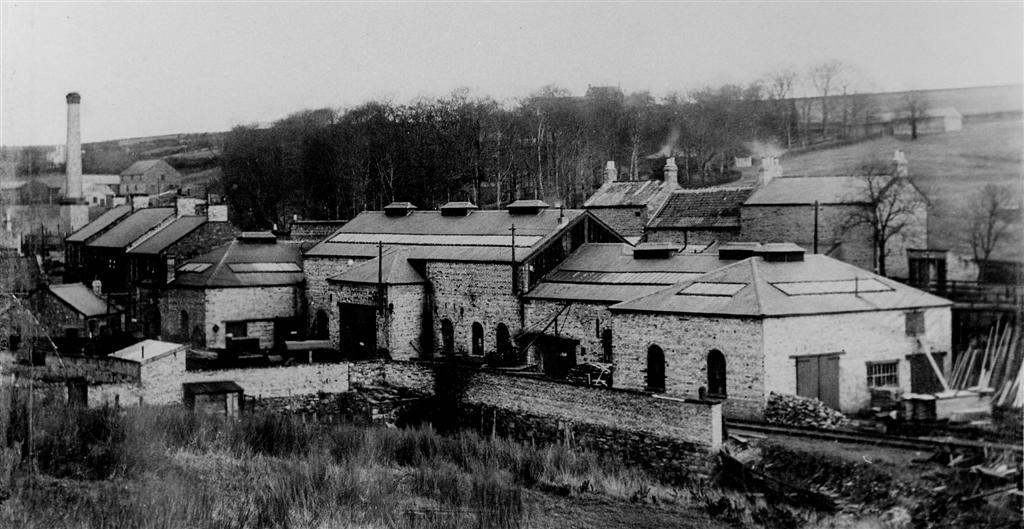

Below left Cowen's High Yard (Yard No. 1) and right, the Low Yard (Yard No. 2) in their heyday and beneath as they are in November 2013.

The High Yard is fairly intact but the Low Yard has just a few dilapidated fragments remaining.

Let us start at the beginning. Bricks have an ancient pedigree. They are a man made ceramic (baked clay) block used in masonry construction and they are known to have been used as far back as 7500 BC in the Middle East. There is evidence of their use in China in 2000 BC and in Europe from the times of the ancient Greeks and Romans. The British industrial revolution saw a massive increase in brick manufacture and usage, accelerated in particular by the gradual transfer from hand moulded bricks to mechanised mass production in the early nineteenth century.

The clay for bricks was usually found under coal seams. This was a convenient coincidence as the coal needed to bake the bricks was readily at hand. Masonry bricks contain - -

silica (sand) 50/60% by weight

alumina (clay) 20/30%

lime 2/5%

iron oxide - up to 7%

magnesia - up to 1%.

Compared with the various types of bricks for normal building purposes a special category is that of fire brick. These are used to line furnaces, kilns and such like and need to withstand very high temperatures without crumbling. These have an aluminium oxide content that can be as high as 50-80% (with correspondingly less silica).

The craft of brick making began in Blaydon Burn around 1730 and even 70 years earlier fire clay was being excavated from the burn and taken to Paradise, on the north side of the Tyne, to make bricks (Bourn). Anthony Forster began his brick making business in the burn soon to be joined by his brother in law Joseph Cowen (later Sir Joseph 1800 - 1873) in a successful partnership. They made fire bricks and also specialised in industrial gas retorts which were of superb quality and by 1844 these retorts were made as a single integral piece rather than from several parts. The retorts attracted much attention in the Great Exhibition in London (a huge world trade fair) in 1851 and the International Exhibition, also in London, in 1862. There an eminent gas engineer, Mr Lowe, commented enthusiastically on the exceptional ability of the Cowen product to withstand very high heat due to freedom from iron achieved by great care in blending different clays and due to following the Chinese practice of leaving the clay for years exposed to all weathers, turning it frequently over, whilst trained employees removed rogue fragments that might degrade the clay. The Blaydon Burn fire clay was, by good fortune for Cowen, absolutely ideal for the purpose – it was just about the best you could get. Lowe went on to say “Along with extreme care in the manufacture of the products all this is the secret of Cowen's fame”. Eventually Cowen bought out Forster and continued to expand the business helped by a superb product, an increasingly international reputation and spiralling demand.

The son Joseph Cowen Jnr (1829 – 1900) took on the running of the business. By now there were two brickworks - Yard 1 on the burn just west of Winlaton and Yard 2 at the north eastern (Blaydon) end of the burn near the confluence with the Tyne.

Just as an aside – it is legend that Cowen Jnr, who was a commited political activist of radical views, used consignments of bricks to send illicit materials to his radical contacts around Europe. The political satirists nicknamed Joe Cowen Jnr "The Cowen Brick" - a wry comment on his unswerving political views and his renowned family business.

Consignments of Cowens fire bricks and gas retorts were exported all over the world – particularly Europe and countries forming part of the then British Empire. He also produced the Lily Brick (a normal building brick) from his Lilley Drift Mine and Brickworks at nearby Rowlands Gill and High Spen. Many local buildings, terraced rows etc. built with the distinctive light buff Lily Brick are still extant around Tyneside. Even after over 100 years they show no signs of deterioration or spalling due to frost that is typical of some poorly made modern bricks.

The Blaydon Burn brick yards continued on into the 1960s when the supply of suitable clay began to run out. This and cheaper, though inferior, competition gradually brought this famous family business to an end. Nowadays only a few isolated fragment of Yard 2 remain but Yard 1 is still fairly intact being used as a vehicle maintenance depot and storage yard. The buildings stand proud as an epitaph to a golden age.

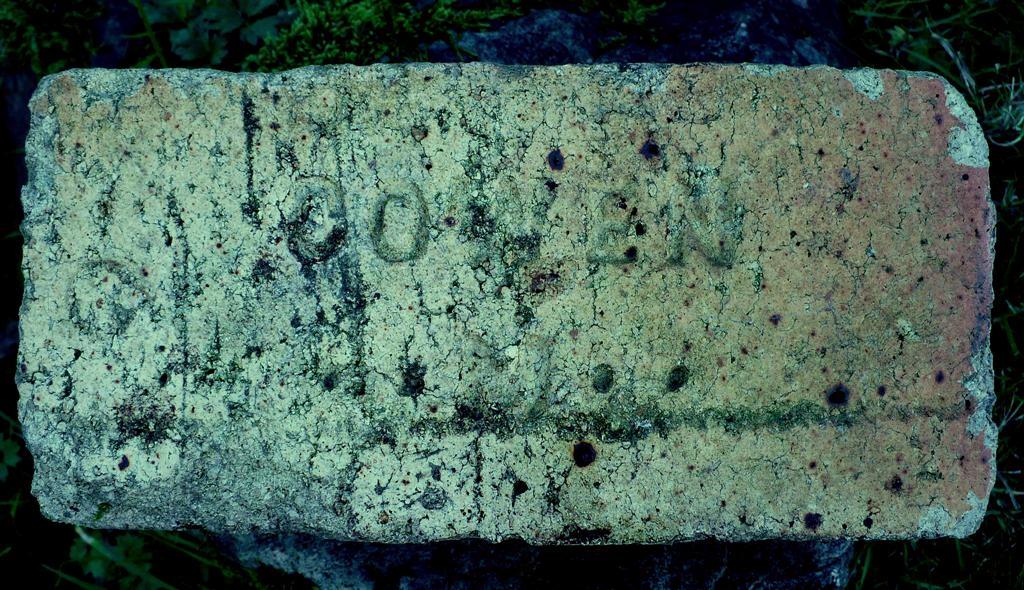

Older bricks were stamped COWEN and prior to automated production were hand moulded. A good moulder could make in excess of 2500 bricks in a day. Later bricks were stamped COWEN M - I've read that these were produced some time after 1926 at the Low Yard site but in contradiction I've elsewhere read that Cowen M signified the bricks made by automated production (M for manufactured) which replaced the hand moulded method in the mid 1800s. I don't know which explanation, if either, is correct.

Dates. I believe the business existed under the name of Joseph Cowen & Co from 1823 to 1904. The lower yard became operational in 1838. I'm advised the firm then passed into other ownership of Priestman Collieries Ltd, who took control of the other Cowen holdings too. This would be shortly after Joseph Cowen Jnr passed away but all the locals knew it as Cowen's Brickyard, right up to eventual closure in the 1960s and even today when reminiscing about it.

They're everywhere!

I the spring of 2013 I was contacted by Susumu Mizuta, a Japanese researcher studying architectural history. He told me of Cowen fire bricks collected on Amami-Oshima island located south of Japan. He has researched a sugar factory constructed there, and Cowen's bricks were excavated from the site of the factory. The sugar factory was one of earliest modern factory in my country, equipped with modern sugar machines in a brick building built under the superintendence of British engineers and constructed around 1866. The building was completely destroyed long ago and any there are no remains but the fire bricks are now preserved in the local museum. Sincere thanks to Susumu for this information and for sending the photos just below.

PS. He is still trying to establish the origins of the Stephenson brick (see photo) also found at the site.

In the autumn of 2013 I was contacted by Kathryn Archer of Hobart, Tasmania, Australia. She had just uncovered a Cowen fire brick in a cottage she is renovating. The cottage was built in May 1900. Sincere thanks to Kathryn for this information and for sending the photos just below. They show the brick and the fireplace. The brick was hidden under paint behind a wood burning stove.

In the late summer of 2016 I was contacted by Gavin Edmond Hodgkinson resident in Germany. Whilst on holiday in Guadeloupe he found a Cowen brick, see picture below. Whilst now a French region, the British held the islands of a number of occasions and British bricks will have been on board their merchant ships as they were also ideal for ballast. At this particular sugar refinery on the island they had been used to build underground vaulted cool storage rooms, the actual sugar refinery building itself, and the chimneys. Sincere thanks to Gavin for supplying this information.

In April 2018 I was contacted by Flint Benson of Washington State found this Cowen 4 brick in a nearby creek. It was from an 1890-1920 cedar shingle mill. He traced the brick back to an old kiln there (see photo). There were other bricks there too, “Livermore” California, “Atlas” California, “Bonnybridge” Scotland, “Tcarr” England, “Kilgaurd” Abbotsford BC and “Clayburn” Abbotsford BC. Amazing! We both wonder why the '4' on the brick. Anyone know? Thanks to Flint for this information.

My thanks to Stephen Kucharski of Oregon, USA who contacted me June 2018 to advise of this Cowen brick in woods near the small town where he lives. He is trying to find out how it came to be there. Could it be related to old gold mining activity in that locality? Whilst researching the Cowen brick he has found there is one at Alcatraz in San Fransisco.

My son found a Cowen 4 brick in Blaydon Burn in late July 2018. Earlier Flint Benson reported finding one in Washington State, USA. We would like to know the significance of these different numbers if anyone can throw any light?

Wherever next? My thanks to Antonio Falchi who contacted me in March 2019. He lives in Sardinia and while snorkelling in the beautiful Sardinian Sea, off Porto Torres, discovered these Cowen bricks . The first photo was taken underwater, the others when some of the bricks were removed to dry land. Not just Cowen bricks but others too. Does anyone recognise the other manufacturers?

More fire bricks. In Australia. Thanks to Robyn who got in touch October 2019 to advise of several scattered around the Belmore chimney where copper and lead were smelted at Bombala, NSW. The bottom two photos show an aerial view of the site of the ruins then a curiosity, a brick with what seems to be the letter C? Is this a Cowen brick? If anyone knows please E Mail to let us know. Thanks.

Thanks to Bjorn for sending me this photograph below of a Cowen brick lying in a ditch in Hilo, Hawaii. February 2020.

Cowen bricks in Oregon, USA.

My thanks to T Bo who contacted me on 7th May 2020 to advise of a visit to an old farm near an old lumber mill on the Yaquina river on the Oregon coast near Newport and discovered hundreds of Cowen fire-bricks laid as a walkway.

My thanks to Wouter from Belgium who contacted me on 23rd June 2020 to advise that he found a Cowen brick back in 2011 in the Ypres area, at the battlefields of WW1. See photographs below.

My thanks to Eileen & Eric from Washington State, USA who contacted me on 3rd March 2021 to advise that they had a Cowen brick hanging in a special mounting (photo below) with a rather nice story behind it. With their permission I've quoted it verbatim below.

"My neighborhood was built around 1900. Three doors down from our house, there is a house that looks normal from the outside, but the inside is an entirely different story. It was built around an old train car. There are remnants of the old metal roof in the attic! About ten years ago, we got to be friends with the owners. They mentioned that at one point, a rockhounder lived there. The backyard was full of half buried obsidian, agates, and petrified wood, as well as a large pile of bricks that was rotting under the moss. They dug up the bricks and built a walkway in front of their house. One day, we noticed the Cowen brick... something that for most people wouldn’t have been a big deal, but it is our family’s surname. When the neighbors moved out of that house, they dug up the Cowen brick and brought it to us as a gift. It hangs by our front door.

It appears we have some genealogical research to do on the Cowen side! We don’t have much info of the US family other than that they showed up in the Tennessee Valley sometime in the 1800s, migrated to Montana, and snuck across the border to Washington to work on the Grand Coulee Dam during the Depression. The rest, as they say, is history."

Thanks to Faye and Ricky from Victoria, Australia who contacted me to advise they just found this Cowen brick today (19th May 2021) while taking down an old chimney at their home. Photo below.

Thanks to Torsten who contacted me to advise he just found some Cowen bricks today (29th May 2021) in a second hand building yard near Flac in Mauritius. They were taken from a sugar mill. He found them in a mix of French bricks. The French bricks are mid 19thc. Photo below.

Thanks to Daniel who contacted me on 29th October 2021 to advise he found Cowen bricks in Hawaii, at the 'Hawaii Institute of Marine Biology' which is on Moku O Loe island which is off Oahu. Photos below.

Thanks to Dave who contacted me on 22nd May 2022 to advise of Cowen bricks which used to be in an assay office in Murphys. This is California gold rush country. Probably arrived at San Francisco via The Horn used as ballast. They are now in a pizza oven. Photos below.

Thanks to Richard who contacted me on 6th February 2023 to advise of a Cowen brick at University Heights, City of San Diego, California. See photograph just below.

Thanks to Jost who contacted me on 16th November 2023 to advise of Cowen bricks in the beautiful Seychelles where he now resides. The top set of four photos are from there, also with idyllic views of the Indian Ocean. He had made one of his excursions into the mountains and came across the ruins of an ancient cinnamon oil distillery and there they were. He took one of the Cowen firebricks home as a souvenir. Then, on a recent trip to the neighbouring island of Mauritius, he visited a wonderful old plantation house with botanical garden and restaurant. After lunch while relaxing in that old garden under very old Mango trees to his great astonishment the bricks of the floor were the same, like those in the mountains of the Seychelles. The place in Mauritius is "Chateau de Labourdonnais“. As shown in the lower set of three photos.

My thanks to a resident of the San Francisco Bay Area who contacted me in April 2025 to advise of a Cowen 6 brick found buried at the home address. It poses the question of the reason for Cowen's naming of Cowen 6, Cowen 4 (see earlier post) and whether there are other names in a numerical sequence and why. Can anyone throw light on this?

Roly Veitch

11th November 2013

Updated 12th April 2025

For more information on our local area history, our unique dialect, our wealth of dialect songs and other topics please visit the home page menu - link below.

Back to Home Page